Plastic Pipe Welding

Welping supplies a range of equipment, in the form of butt welding, electrofusion welding, socket welding and plastic extrusion welding. The technology is suitable for many types of plastic pipe including PE, PP, PVDF, plus many more.

With industry’s comprehensive line of plastic welding equipment in China.

Plastic Pipe Welding Categories

Plastic Pipe Welding Categories

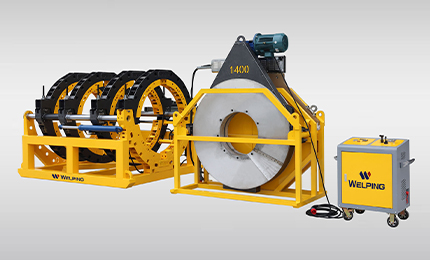

Hydraulic Butt Fusion Machines

We are a professional Hydraulic Butt Fusion Machines (Butt Fusion Machines) manufacturer and supplier in China. Here you can find high-quality products in a competitive price. Also we supply OEM service of products for you.

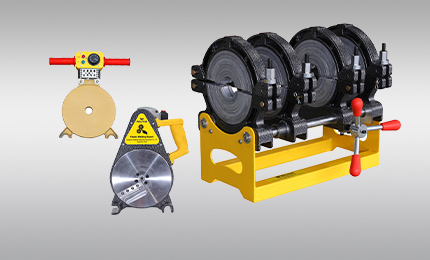

Read MoreManual Butt Fusion Machines

WELPING butt fusion machines designed to carry out butt fusion operations correctly and efficiently, for plastic pipes, material of PE, PP, PB, PVDF etc. The butt fusion machine are available to cover pipe size ranges from 63mm to 2200mm polypropylene pipes.

Read MoreAutomatic Butt Fusion Machines

Fully Automatic Butt Fusion Welding Machine,butt fusion, polyethylene, field welding,Thermoplastics Pipe Welding Machine,HDPE Pipe Welding Machine,Pipe Welding Machine,Polyethylene Pipe Butt Welding Machine,Polyethylene Pipe Fusion Welding Machine

Read MoreElectrofusion Machines

Electro-Fusion Welding Machines & Tools for HDPE MDPE Polythene Gas & Water Pipes & Fittings.Welping electrofusion welding machine with welding couplers up to Ø 1000mm. It also supports the multi languages, data recorded, data review and transfer.

Read MoreSocket Fusion Tools

Socket fusion welders for joining pipes and fittings, in compliance with the standards in force. They feature an aluminum heating plate and a practical, heat-insulated plastic handle. They can weld HDPE, PP, PP-R, PVDF pipes and fittings, and they’re characterized by different shapes and working ranges, suitable for different applications.

Read MorePlastic Extrusion Mahicnes

The professional powerful extrusion welder for plastic fabrication and civil engineering.Our powerful hand extruder is well-suited for welding thermoplastics like PE and PP. This powerful Weldy hand extruder can also be used for agricultural work, construction, and welding membranes.

Read MoreLatest News

Latest News

- Seamless Connections for Critical Infrastructure: How Welping’s HDPE Fusion Machines Power Modern PipelinesThis is where **Welping Machinery**, a leader in welding technology, steps in with its advanced HDPE butt fusion welding machines, ensuring seamless and durable connections for diverse applications.More

- Picking the Perfect HDPE Pipe Fusion Machine for Your Engineering ProjectWhen it comes to engineering projects involving HDPE pipes, choosing the right butt fusion welding machine is key. HDPE pipes are popular due to their corrosion resistance, flexibility, and durability.More

- Common bad operation and treatment methods of HDPE pipe welding machineWhether you're working on municipal water systems, irrigation projects, or industrial piping, mastering the art of HDPE pipe welding is crucial for ensuring the integrity and longevity of your installations.More

Plastic Pipe Welding Manufacturer

Plastic Pipe Welding Manufacturer

What is difference between plastic welding and fusion welding?

Inside the plastic welding, additionally referred to as the stress welding, the portions of metallic to be joined are heated to a plastic kingdom and then pressured collectively by means of outside stress while in fusion welding, also known as the non- pressure welding, the material on the joint is heated to a molten nation and allowed to solidify.

What is the main difference between plastic welding and metal welding?

Plastic welding is based totally on melting and fusion of the fabric (in a feel, like many steel welding approaches, along with arc, resistance or laser), but much lower temperatures than skilled in metal fusion processes.

Is plastic welding strong?

As said, plastic welding can be very sturdy and strong if accomplished efficiently, however plenty of things will have an effect on its sturdiness, from material to the experience of the welder. Bad or incorrect welding procedure is regularly to blame for a drop-in durability expectations.

How do you weld HDPE plastic pipe?

Heating the HDPE to the best temperature and then fusing it together with the alternative piece is commonly enough to fully weld the 2 portions collectively.You can work with WELPING butt fusion machine ,Electrofusion welder and Plastic Extrusion Welder hot gun etc to help you weld HDPE pipes.

Can you use a heat gun to weld plastic?

Plastic welding creates a very strong bond among the materials that is very tough to interrupt. You can weld tarpaulin and other flexible cloth using a wide slot nozzle from WELPING hot air gun. Placed the nozzle among the two portions of plastic you want to warmness and keep heating.